Digital hourglass

Unlike most ordinary kitchen timers this digital hourglass is gesture

controlled and uses six LED rings instead of an LC display. Originally the

project was part of a university course “embedded systems”, but in the end

it took two years – way more than one semester – until it reached its current

state.

Currently the project lacks a catchy name. Its internal name is “sanduhr”

(hourglass) due to its user interface and the yellow LEDs used. Some people

refer to it as “egg timer” or “iUhr”, which sounds like “Ei(er)uhr” (egg timer)

in German.

Usage

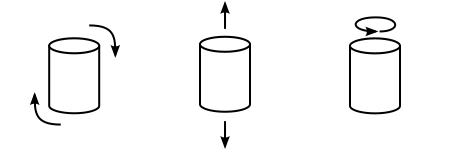

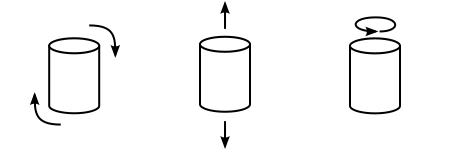

The device is controlled with three gestures: Flip, shake and spin.

When idle shaking once starts the time selection mode. First a coarse

selection in steps of 10 minutes is performed by spinning the device. After a

second shake up to five minutes can be added or subtracted, depending on the

spin direction. The maximum time is 65 minutes. Flipping the device starts and

stops the timer. The user is notified upon timer expiration by flashing LEDs

and a short beep tone.

Hardware

The device consists of two different boards: The first one holds three LEDs

each and the other one control logic and a speaker. Altium design files are

available here (signature). Reading the errata before using them is

highly recommended.

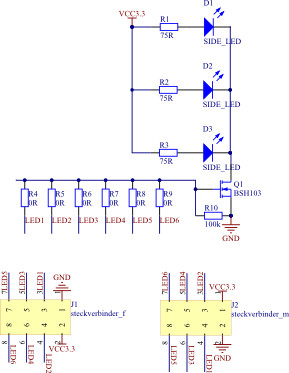

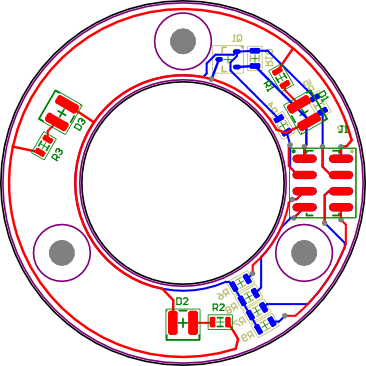

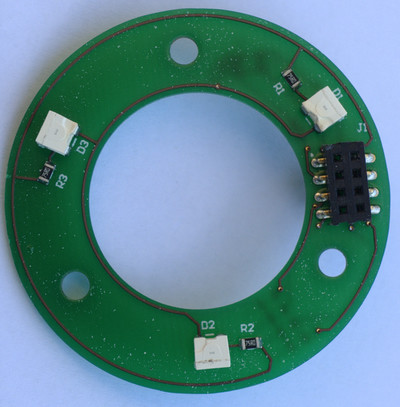

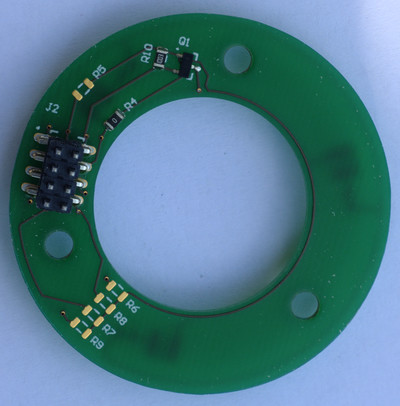

LED board

This is the LED board. It is equipped with three side LEDs from Osram. R4–R9

connect one of the input lines of J1 and J2 to the transistor Q1 with a 0 Ω

resistor. Thus the same, configurable board can be used for all six rings.

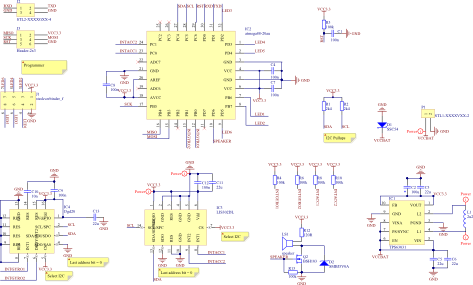

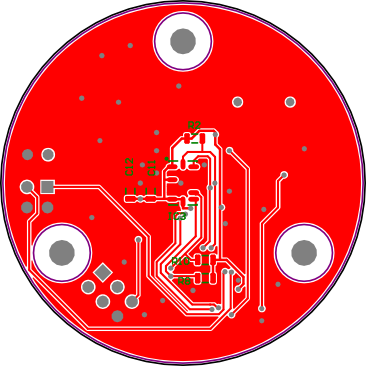

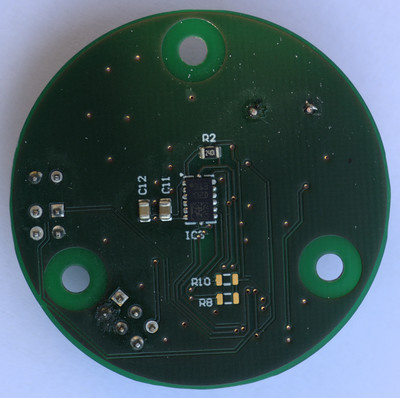

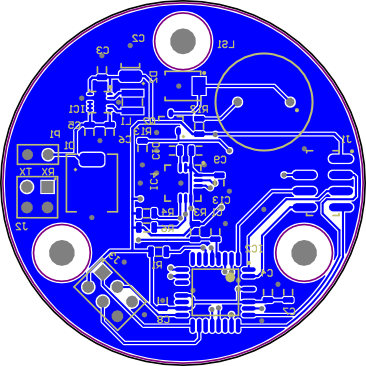

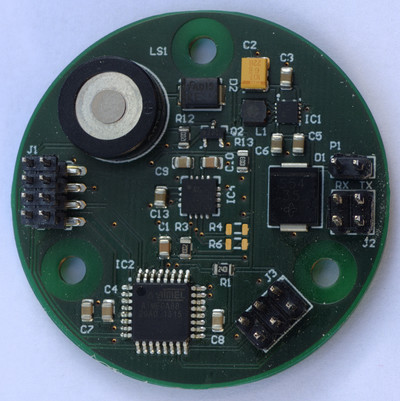

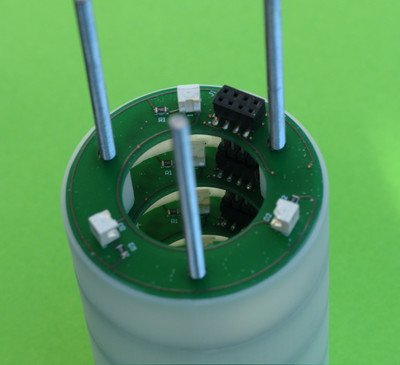

Control board

The control board’s “heart” is the 8 bit microcontroller ATmega88-20AU (IC2)

running at 1 MHz. A L3GD20 gyroscope (IC4) and LIS302DL accelerometer (IC3,

on the bottom side), both made by ST, are used to detect gestures. They are

connected to the microcontroller through the I2C bus, whose pullups

are R1 (SDA) and R2 (SCL). There’s also two interrupt lines per sensor

connected to the CPU (INTACC and INTGYRO). The pullups R4, R6, R8 and R10 for

these signals are not equipped, because the microcontroller’s IO pins has

internal configurable pullups.

A Texas Instruments buck boost, TPS63031 (IC1), converts 1.8–4.5 V input

voltage to 3.3 V output voltage that powers all components. Since there does

not seem to be any internal protection circuitry diode D1 protects it from

batteries attached with reverse polarity.

Other notable components are pin header for LEDs (J1), power (P1),

programmer (J3) and UART (J2), as well as the speaker (LS1).

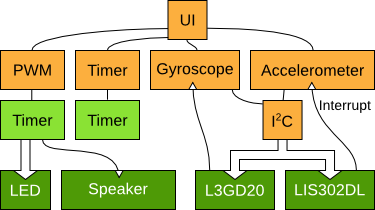

Software

The software (local repository), like most of embedded code, consists of

a number of state machines. The user interface (UI) is biggest one. It controls

the whole device by accessing the drivers for PWM, timer, gyroscope and

accelerometer, which provide a thin layer of abstraction and should be

reusable. Interrupts are handled in asynchronous fashion: They set a flag and

wake up the main loop that decides what to do next.

Gesture recognition

One goal was gesture recognition without polling the sensors. That does not

work for the spin gesture, which is not that bad, since its recognition is only

required in time selection mode. Thus the sensor can be switched off most of

the time. That’s not the case for the accelerometer, which is used to detect

flip and shake gestures, though. Fortunately the sensor comes with so-called

“free fall interrupts”, which trigger after the sensor readout exceeds or falls

below a programmed value for programmable time.

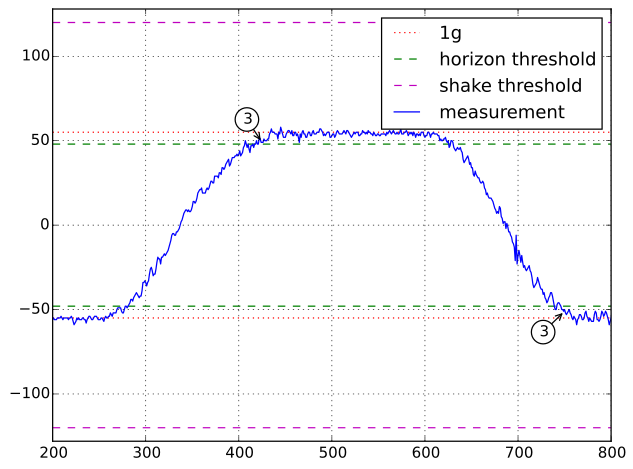

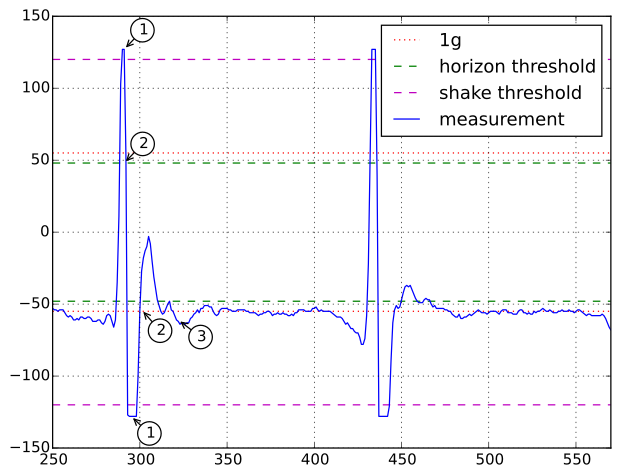

The flip gesture is pretty straight-forward. As soon as the the (absolute)

measured value rises over the horizon threshold for at least 150 ms an

interrupt is fired. It triggers a sensor readout to determine the actual

orientation. The horizon threshold is slightly below 1 g. The graph below shows

continuous sensor measurements for two slow flips:

Shakes can be detected with a second high threshold. The sensor is configured

to map ±2 g to a signed char (-128 to 127) and the programmed threshold is

slightly below that value. In the following graph three events can be observed

(ignore the clipping at 1):

- The value raises above the shake threshold, triggers an interrupt and

increments the shake counter. A count of two corresponds to one shake

gesture.

- A flip gesture is not recognized, because peak 1 is shorter than 150 ms.

- Now a flip is detected and processed as described above

Casing

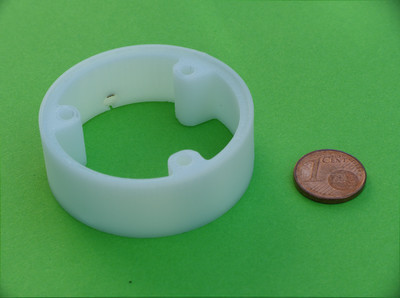

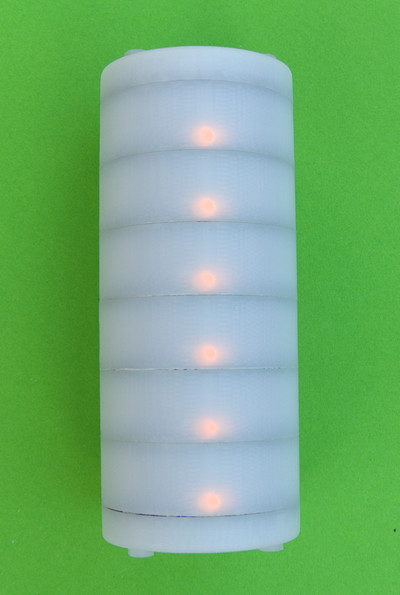

The casing has three parts: A ring that sits between the LED PCBs

(first picture) and a separate cap (second picture) for top and bottom (again,

see errata). They have been designed with SolidWorks and 3D printed in ABS

white. Design files are available here (signature). Three threaded rods

and six plastic nut (three on each side) hold everything in place, as seen in

the last two pictures. The final design’s height is 9.4 cm.

Cost

There are several aspects, and the first one is time. Designing the PCB took

about 50 hours. This is the first PCB I designed and I was not familiar with

Altium Designer before. Initial soldering with hot air took a whole work day

(about eight to nine hours). A few more hours can be added for replacing

components by hand, including the small buck-boost (QFN-10). Finally I spent

about 100 hours designing the software. That includes reading IC documentation,

getting familiar with embedded programming (my first embedded project) and

endless hours of debugging.

Next up, money. The table below was up-to-date in 2013/2014 and does not take

shipping into account. However prices include 19% VAT/GST.

| Part |

Quantity |

Cost [€] |

|---|

| PCB production (at PCB-POOL) |

1 |

130.35 |

| Casing (3D printed) |

1 |

32.14 |

| Gyroscope (L3GD20) |

1 |

11.01 |

| Accelerometer (LIS302DL) |

1 |

4.09 |

| Microcontroller (ATMEGA88-20AU) |

1 |

3.99 |

| Buck-Boost (TPS63031) |

1 |

3.36 |

| LED (LYA67K-J2M1-26) |

18 |

2.95 |

| Transistor (BSH103) |

6 |

2.47 |

| Capacitor (22 µF) |

5 |

2.20 |

| Transducer (ABT-407-RC) |

1 |

1.16 |

| Capacitor (100 µF) |

1 |

1.10 |

| Diode (SSC54-E3/57T) |

1 |

0.43 |

| Resistor (75 Ω) |

18 |

0.27 |

| Diode (SMBJ5V0A) |

1 |

0.25 |

| Inductor (NR3015T2R2M) |

1 |

0.21 |

| Resistor (100 kΩ) |

6 |

0.19 |

| Capacitor (100 nF) |

6 |

0.16 |

| Resistor (0 Ω) |

6 |

0.08 |

| Resistor (2.4 kΩ) |

2 |

0.08 |

| Capacitor (10 nF) |

1 |

0.02 |

| Resistor (120 Ω) |

1 |

0.01 |

| Total |

1 |

196.52 |

Several parts are missing in this table, including connectors for LED and

control boards.

Producing small quantities of PCBs is very expensive. With 100 units the price

for PCBs could be cut down to 5.70 € per device. The same holds true for other

components like sensors and ICs and I estimate for 100 devices the hardware can

be bought for 25–30 € each (without actual assembly and casing). That’s still a

pretty expensive hourglass.

Errata

The hourglass presented is a prototype and suffers from typical flaws that

could have been easily prevented at design time.

The board lacks markings for power supply +/- and a board revision. One of the

two ground pins on the UART pin header (J2) should have been a VCC pin. The

holes in the PCB are not equally spaced, i.e. they do not form a isosceles

triangle. Designing the case would have been easier if they did.

I used two separate sensors and found out MEMS modules with both, gyroscope and

accelerometer in one package, exist only after producing the PCBs. These

sensors are also less expensive than buying two separate devices, so it would

make sense to use those. Initially I ordered two TPS63030 instead of the

TPS63031. Obviously the device did not power up and I had to replace them.

After doing so the device still did not boot, because the reset resistor (R3)

and capacitor (C1) were too big. Replacing them with 10 kΩ and 10 nF

respectively worked.

Additionally there are unresolved issues regarding the design itself:

The initial idea was to illuminate the whole ring with three LEDs. As the

picture above clearly shows this goal was not achieved. Only a tiny spot of

the casing is bright, leaving everything else dark.

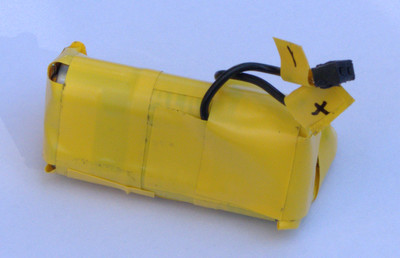

Also there is no battery solution yet. For programming I’ve been using an

external power supply, which is a little cubersome when testing gestures, but

works most of the time. Since the device was supposed to be battery powered I

also created a custom battery pack consisting of three AAA batteries, aluminum

foil and tape (see picture below). It fits perfectly inside ring hole, as

it was supposed to. However this is not a permanent solution. Commercially

available battery holder that fit don’t exists as far as I know, so a 3D

printed solution might be the last resort.

The prototype’s main problem is power usage, as the table below suggests.

| Idle |

3 mA |

0.010 VA |

| Timer |

60 mA |

0.196 VA |

| All LEDs |

393 mA |

1.268 VA |

The PWM implementation might not be ideal yet, but further optimizing it won’t

reduce the power usage significantly I believe. Compared to an LC display 18

LEDs will always use more power, which is the reason most battery powered

consumer electronics prefers the former.